Project-Thesis & Training

In the power distribution industry today, utility companies are trying to come up with a solution to increase the efficiency of distributed power. One way of achieving this task is by improving the power factor of a system by adding power factor correction capacitor. Power factor improvement is a very important aspect of power distribution. Without a good power factor, there cannot be an efficient means of transporting energy over long distances due to the losses associated with moving power through a wire. This action has led to multiple studies on power factor correction. In order to achieve maximum efficiency, we had to increase our power factor as close to unity as possible. Power factor corrector (PFC) is usually achieved by adding capacitive load to balance the inductive load present in the power system. The power factor of the power system is constantly changing due to variations in the size and number of the motors being used at one time. This makes it difficult to balance the inductive and capacitive loads continuously. Wasted energy capacity, also known as poor power factor, is often overlooked. It can result in poor reliability, safety problem and higher energy costs. The lower your power factor, the less economically your system operates. There are many benefits to having power factor correction. As a customer the cost doesn’t get passed on for having a low power factor. As a utility company, equipment has a much longer life span and maintenance costs remain low.

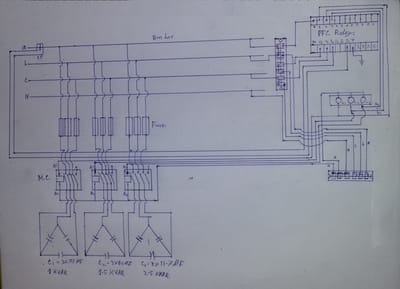

Here mention two image, first image of PFI project and second is for connection diagram of this project.

Our project and thesis is PFI Plant (5 KVAR). We used for this project several electric equipment. There are shows in a doc file .

Required equipment list for (5 KVAR) PFI Plant:

| SL. No. | Name of equipment Image | Description of equipment | Quantity |

| 1. | PFC Relay | a). Rated working current=0-5A (ac). b). sensitivity=60mA. c). Useable 12 step, we used 3 step. | 3 Piece |

| 2. | Current Transformer | IP:IS = 30A:5A | 1 Piece |

| 3. | 3 phase Magnetic Conductor (MC) | Brand of MC is ABB | 3 Piece |

| 4. | 3 phase capacitor | a). 3x5.5μF b). 1 KVAR | 1 Piece |

| 5. | 3 phase capacitor | a).3x8.2μF b). 1.5 KVAR | 1 Piece |

| 6. | 3 phase capacitor | a).3x13.7μF b). 2.5 KVAR | 1 Piece |

| 7. | Fuse | 32 Amp | 12 Piece |

| 8. | Bus bar | Copper bar | 4 Piece |

| 9. | Connector (6 pin) | As fidder | 2 Piece |

| 10. | Indicator | Green color | 1 Piece |

| 11. | Indicator | Yellow color | 1 Piece |

| 12. | Indicator | Red color | 1 Piece |

| 13. | Conductor | a). 25 RM b). Red, Yellow, Black, & Green color. | 11 Meters |

| 14. | Conductor | a). 15 RM b). Red, Yellow, Blue, Black & Green color. | 11 Meters |

| 15. | Insulator, L-supporter, Insulation Tube, Board, Relay Box, Cable Tie, Cable Clip. | Use for design of PFI Plant. | As necessary |

| 16. | Cable Lugs (O-Type, U-Type, I-Type, Jack Type) | Use for design of PFI Plant. | As necessary |

Project 2: Motor winding

Project of Motor winding of ceiling fan. This motor is single phase induction motor.

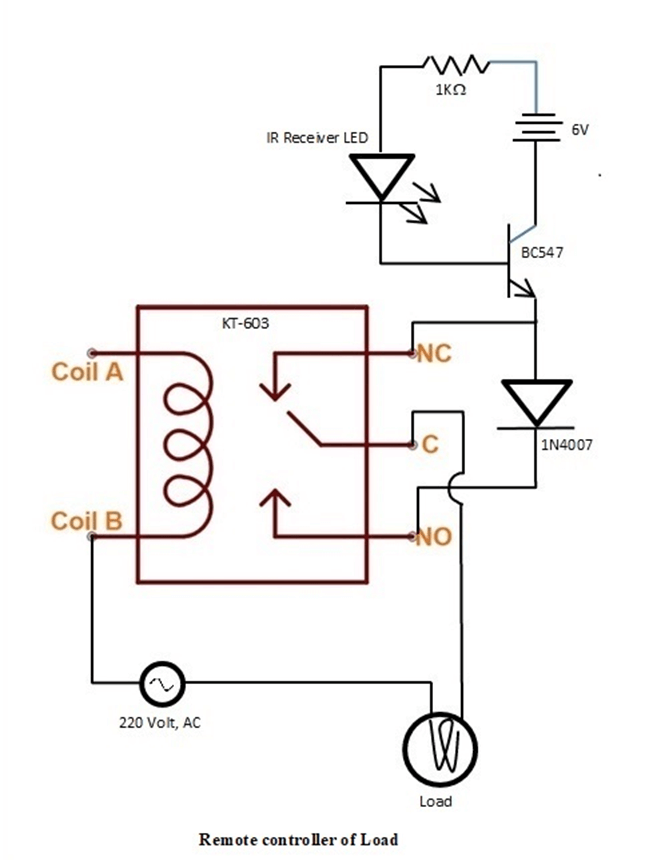

Project 3: Remote controller of Load

The 21st century has been declared as the century of science and technology. It touches of technology in our daily life. Due to science and technology, nowadays it is possible to do anything sitting in one place. But why do people go to the switch board to turn on or off the lamp or fan! The use of remotes for remote control of lights and fans is increasing at a significant rate. So I started working on this project

A table is mention below of required equipment list for Remote controlling device of fan and lighting load.

| SL. No. | Name of Component | Specification of Component | Quantity |

| 1. | Resistor | 1 KW | 1 Piece |

| 2. | Diode | Model: 1N4007 | 1 Piece |

| 3. | Transistor | nPn, Model: BC547 | 1 Piece |

| 4. | Relay | Model: KT-603 | 1 Piece |

| 5. | Infrared Light Emitting Diode | 1 Piece | |

| 6. | Battery | 6 Volt, DC | 1 Piece |

| 7. | AC Supply | 220 Volt | |

| 8. | Load | Fan or Lighting load |

The circuit diagram of is mentioned below

Training 1: Industrial attachment

Industrial attachment program for three months in Power Grid Company of Bangladesh (PGCB), Patuakhali, near Patuakhali bus stand, Patuakhali.

Training 2: Official training

Official training (based on ERP) for three days at Star Paradise Ltd, Awal Center, (13th floor), 34, Kamal Ataturk Avenue, Banani C/A, Dhaka-1213.